Slewing Ring Bearing

Slewing Ring Bearing

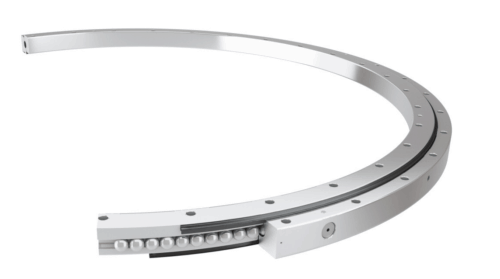

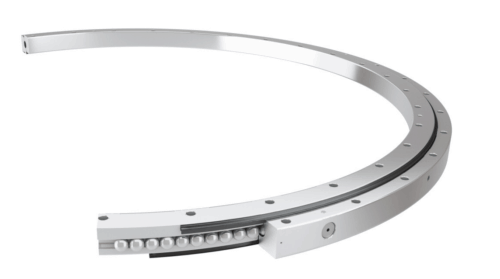

Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.

Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.

Slewing Ring Bearing Types

LYMC Bearing is pleased to offer slewing ring bearings from high-end brands, including Rothe Erde® (Rotek), Silver Thin™, and Scheerer Bearing Corporation. Depending on your application needs, these bearings are available in a variety of designs.

Series 1000 Single Row Ball Slewing Ring

The Series 1000 is a gearless-only bearing model composed of chrome-alloy steel balls without spacers in unhardened raceways within steel rings.

Series 2100 Single Row Ball Slewing Ring

The Series 2100’s single-row design offers four-point contact in induction-hardened, offset raceways.

Series 3000 Single Row Ball Slewing Ring

The Series 3000 is an adaptation of the four-point contact slewing ring constructed with offset hardened raceways, quality raceway wrap, and sturdy ball separators.

Series 4000 Two Row Ball Slewing Ring

Series 4000 is built with greater internal clearance than the series 3000 model for enhanced mobility.

Series 5000 Cross Roller Slewing Ring

The Series 5000 Cross Roller is built V-groove style raceways, to provide two paths for rollers in each ring.

Series 6000 High Speed Slewing Ring

Our single row Series 6000 is a high-speed radial ball slewing ring that can provide raceway velocities up to 3,000 feet per minute with sufficient lubrication.

Series 7100 Vertical Thrust Slewing Ring

Series 7100 Vertical Thrust Slewing Rings are a single-row ball bearing specifically designed to support applications in which the center of force stays inside the diameter of the slewing ring during standard operation.

Series 8000 Vertical Thrust Slewing Ring

Similar to the 7100, the 8000 is a single-row ball bearing that supports vertical movement within the slewing ring’s diameter. The 8000 model offers the lowest cost per unit diameter for heavy, pure-thrust loads.

Series 10,000 Three Row Roller Slewing Ring

The series 10,000 is built with three rows of rollers that move independently for optimal support and freedom of movement in the desired direction.

Series 12,000 Roller and Ball Combination Slewing Ring

The Series 12,000 combines both rollers and balls to account for small movement eccentricities at relatively high axial loads for enhanced load support and stability.

Series 15,000 Wire-Race™ Slewing Ring

Our Series 15,000 Wire-Race™ Slewing Ring includes a replaceable hardened wire raceway, which allows the supporting rings to be created using a wider assortment of materials.

Precision Slewing Rings

LYMC’s precision slewing rings are designed to facilitate highly accurate support and mobility to exacting specifications, including:

- Run-out tolerances within .0003”

- Concentricity within .0003”

- Surface flatness within .0003”

- Parallelism within .0003”

- Bolt hole positions .010” diameter

- Gear precision equals or exceeds AGMA 10 standards

Slewing Ring Bearing Applications

Slewing ring bearings are often relied upon to support loads in very large, heavy-duty equipment. Their exceptional combination of heavy load support and mobility enhancement makes them useful in a variety of industries and applications, including:

- Fifth Wheels on Trailers and Farm Vehicles

- Cranes

- Excavators

- Stackers and Reclaimers

- Lift Truck Rotators

- Turnstiles

- Mining Equipment

- Machining Tools

- Radar Antennas

- Tunnel-Borers

- Log Debarkers

- Coil Winders

- Pay-Off Reels

- High-Speed Capstans

- Large, Precision, and Index Turntables

- Water Treatment Facilities

- Clarifiers, Thickeners, and Rotary Distributors

- Mooring Buoys

- Robotics Equipment

- Medical Diagnostic Equipment

- Bottling Equipment

Slewing Ring Bearings From LYMC Bearing

For more than 50 years, LYMC Bearing has been the go-to provider of top-quality roller and ball bearings for customers around the world. Our selection includes everything from miniature precision bearings to five-foot mill bearings in a variety of styles and materials to suit the needs of your applications. We are dedicated to providing our customers with the right bearings at competitive prices. We offer a wide range of services, including:

- One-Stop Shopping Experience

- Extensive Inventory

- Worldwide Sourcing Network

- Bearing Troubleshooting Capabilities

- Online Product Catalog

- Comprehensive Online Reference Tool

- Same-Day Shipping

- Fixed Price Program

- Guaranteed Customer Support 24/7

- OEM and MRO Expertise

- OEM Parts Interchange Services

LYMC provides personalized and professional service to our customers worldwide. To learn more about LYMC’s top-of-the-line bearing products and solutions, contact us today or request a quote!

SLEWING RING BEARINGS – COMPONENTS(TURNTABLE BEARINGS)

- Inner Ring and Outer Ring

- Rolling Elements

- Spacers, Spacer Balls & Separators

- Mounting Holes

- Seals

- Load Plug

- Taper Pin

- Gear

- Grease Fitting

- Part Numbers

Inner Ring and Outer Ring

Slewing ring bearings are comprised of two rings, each of which contains a precision raceway that is induction hardened on the surface to a specified depth. Each ring is made from a medium carbon steel forging. Silverthin™ SK and ST Series bearings have raceways constructed in a four-point contact configuration, with 45° contact angles as standard. Other raceway configurations are available, such as crossed roller and eight-point contact. These other options are often considered in cases where very high loads or special stiffness requirements are needed.

Rolling Elements

Precision rolling elements (specifically hardened chrome alloy steel balls for Silverthin™ SK and ST Series bearings) facilitate relative ring rotation between the inner and outer rings. Rollers as rolling elements are also often used.

Spacers, Spacer Balls & Separators

Spacers, typically made from a plastic material, are commonly used to separate balls to prevent them from rubbing directly against each other. Sometimes spacer balls are utilized instead of spacers. In this case these are balls that are slightly smaller than the load carrying balls, placed between each load carrying ball. Occasionally, application parameters warrant the use of a separator.

Mounting Holes

Mounting holes are generally spaced around the faces of the inner and outer ring along a uniform bolt circle and equal spacing. These holes can be thru holes, tapped holes, blind tapped holes, counter-bored holes, etc. Sometimes bolt circle or spacing requirements need to be customized to meet the demands of a specific application, in which case custom options are available. In the case of either the standard part numbers listed in this catalog, or other custom versions provided by Silverthin™, the equipment designer, manufacturer, or user is responsible to determine that the mounting design is adequate.

Seals

Seals are provided on each side of the bearing, with their primary functions being grease retention and prevention of some contamination such as dust and debris from entering the bearing. The seals are typically made from an extruded Buna-N rubber strip, and in smaller sizes are a metallic non-contact shield.

Load Plug

Due to the nature of the race hardening process, there is a gap in the race hardness of each race. In that location for the non-geared ring, or the outer ring for ungeared bearings, a hole is drilled to permit the loading of balls into the final slewing ring assembly. This hole is plugged and secured with a taper pin. Note that for the ring where a load plug is not present, an ‘S’ is stamped on the face of that ring at the location of the unhardened gap in the race (also known as the soft spot). Removal of the load plug voids the warranty.

Taper Pin

Secures load plug to the inner or outer ring.

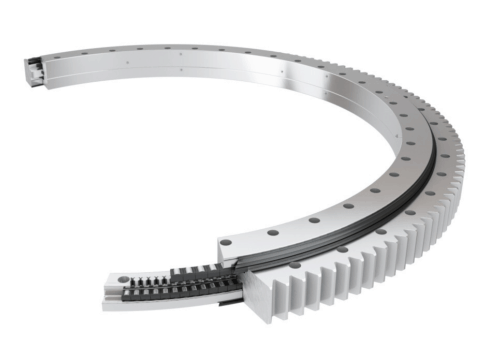

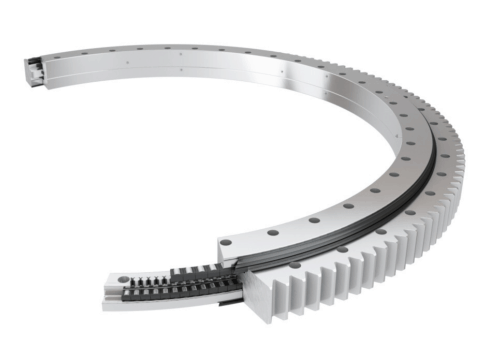

Gear

Slewing ring bearings can be supplied as ungeared, or with gears on either the ID of the inner ring or the OD of the outer ring. Gears are typically a standard stub involute spur gear with backlash provisions and AGMA Q8 quality minimum. Details for each bearing can be found in the enclosed dimensional tables, and drawings are available from Silverthin™ Engineering. Custom gear configurations are also available.

Grease Fitting

At least one grease fitting is included in one of the rings. The quantity may increase with the diameter of the bearing. For bearings with gears, the grease fitting(s) are located on either the ID or OD of the ungeared ring. For ungeared bearings, Silverthin™ ST Series and SK Series slewing rings come equipped to accommodate grease fittings on either the inner or outer ring. Custom quantities, locations and configurations for grease fittings are available.

Part Numbers

Part numbers and serial numbers are etched on one of the faces of the bearing.

SLEW / TURNTABLE BEARINGS

- Bore diameter starting from 50 mm

- Simple installation

- Available in various, individual versions

- Available with internal or external gear and without gear

- Corrosion-resistant types available on short notice

- Generally short delivery times

Turntable bearings – For heavy-duty applications

The rugged ball-bearing slewing rings from Isotech are characterized by their large diameter and large bores with only a small cross-section. They were designed for axial, radial as well as combined axial and radial loads. New design concepts and improved manufacturing processes for the ball-bearing slewing rings, enable our customer’s designers to implement completely new solution approaches. The bearings are very easy to assemble and demonstrate their properties particularly in small, sophisticated and high precision applications such as in the aerospace industry or in the special machinery area.

The bore diameter of the Isotech ball-bearing slewing rings is at least 50 millimeters. The bearings are available with and without gear teeth, optionally in a corrosion-resistant or a customer specific tailor-made design.

Features and benefits of the turntable bearings

- Bore diameter starting from 50 mm

- Simple installation

- Available in various, individual versions

- Available with internal or external gear and without gear

- Corrosion-resistant types available on short notice

- Generally short delivery times

Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.

Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.